23 Jul Webinar: Past, Present, and Future of Lighting Technology in Cannabis Cultivation

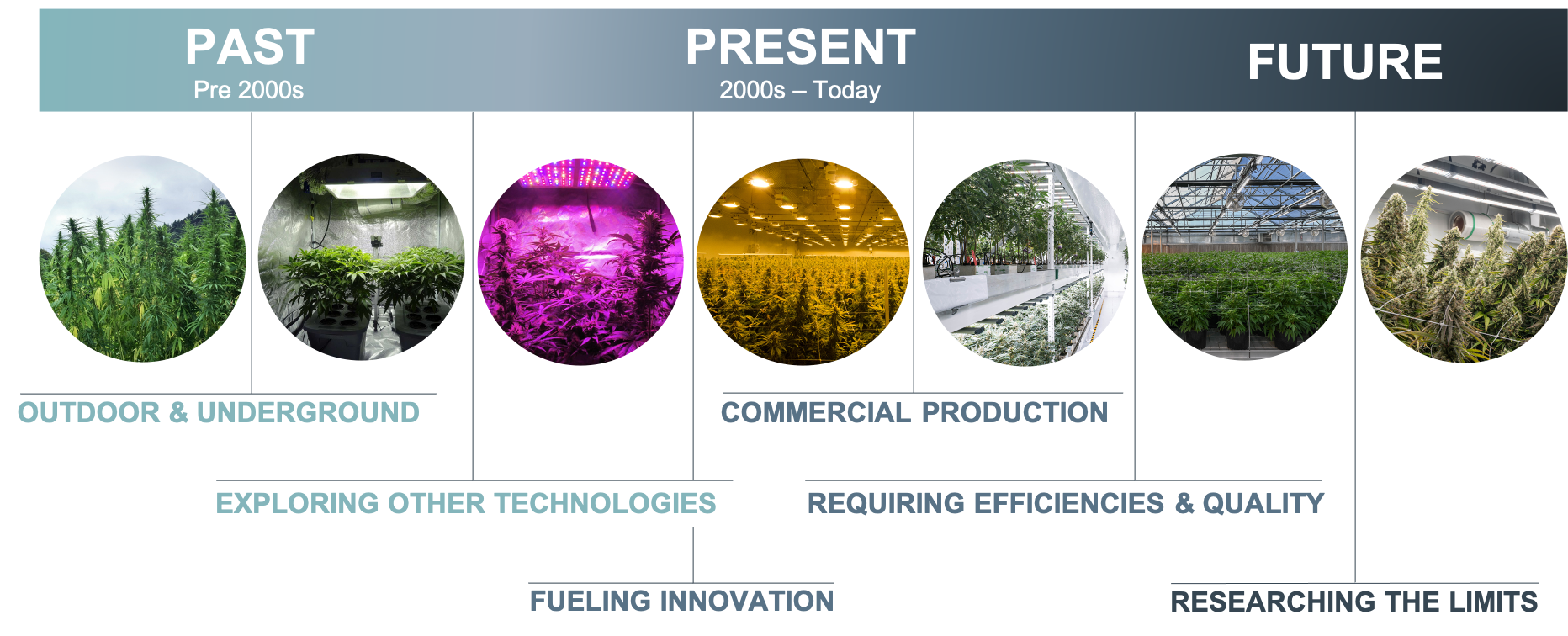

Cannabis production has come a long way since the days of guerrilla gardens in the Emerald Triangle. As legalization spreads across the globe, entrepreneurial growers are eager to figure out the best way to cultivate this valuable crop.

Understanding the evolution of cannabis cultivation is important for empowering its continued growth, and this evolution was detailed in a recent Fluence webinar on lighting technology’s role in cannabis production over the years and into the future.

Past

“We can continue to learn from pioneering work conducted long ago,” according to Fluence horticulture specialist Taylor Kirk, who shared resources used by early growers. For instance, did you know that the popular magazine High Times was launched in 1974? Incredibly, the Marijuana Grower’s Guide, published in 1978 by Mel Frank, remains more than relevant today, as does Ed Rosenthal’s Marijuana Grower’s Handbook (1985).

Lighting strategies from the past included outdoor growing using sunlight and light deprivation techniques, as well as legacy lighting options such as fluorescent, CMH, HPS, and plasma. The light quality was generally broad white with the exception of HPS ,which has a warmer orange hue. Growing outdoors relied heavily on Mother Nature, and crops often suffered from inconsistencies in their environments such as unpredictable light levels, temperature, and other important variables. Overall intensity was considerably lower than the 500-600 micromole range that is used today, expressed in the out-dated measurement of 35,000-40,000 lux.

NOTE: Humans use lumens while plants use PPFD. Learn the importance of measuring the proper horticulture lighting terms in our science article here.

As we consider the past, present, and future of the cannabis industry, Kirk Taylor points to DLI as a crucial concept for its understanding. Today, science and research have revealed much more important data for maximizing growth.

Present

In the current state of cannabis cultivation, Taylor notes that while some of the old resources retain value, we now have much more information available to us. Numerous new publications, peer-to-peer sharing, and up-to-date research are all easily accessible via the internet, putting valuable data within easy reach.

Fluence’s director of horticulture services, Dr. Abhay Thosar, discussed the three primary light sources currently in use: double-ended HPS, narrow-band LED, and broad-spectrum LED, providing light intensities in the 1000 -1100 micromoles range and 43-48 moles DLI.

One of the most pressing issues for growers today is the decision between HPS and LED lighting. In order to shed some light on the relative strengths of the two technologies, Fluence conducted a study that compared HPS to broad-spectra Fluence LEDs. Using 1100 micromoles/m2/sec of sole-source lighting, the study showed a 20-25% increase in production with 30% power savings for plants grown under LEDs. Furthermore, crops grown under broad white LEDs outperformed HPS in total dry yield in all four of the cultivars studied.

Another study compared HPS’s max 1200 micromoles/m2/sec to LEDs producing 1500 micromoles/m2/sec. The results overwhelmingly favored LEDs: 25% power savings and 25-30% yield increases, depending on cultivar.

Future

What should we expect in the future? It’s likely that many more cultivators will continue to switch from HPS to LEDs. The changeover will be easier with more research and accessibility, especially as legalization becomes more widespread. Growers will appreciate being able to use a spectrum designed specifically for plant growth rather than one designed for lighting highways.

The industry will likely continue to push the limits of light intensity. As cultivators learn to better manage crops with higher light intensities, one can expect levels to reach upwards of 2,000 micromoles/m2/sec and DLI values of 85-86 moles. In the future, growers will be able to use spectra strategically to elicit desired results. Furthermore, LEDs will enable growers to use artificial intelligence to manage cultivation facilities remotely and with fewer people.

Even with all these changes, the Fluence team closes the webinar by reminding growers that having a strong partner to help them navigate the upcoming changes to the industry will always be crucial. Fluence’s Horticulture Services team is ready to assist growers every step of the way.

Following the presentation, webinar attendees were invited to submit questions, a few of which are shared below. See the entire presentation here.

Q: In new construction, when selecting a technology, what are three considerations cultivators should apply in their grower trials for accurate and consistent data?

A: First and foremost, make sure you are comparing apples to apples. Your PPFD should absolutely be the same when you’re measuring on the top of the crop canopy. Next, look at the efficacy of the fixtures. Finally, when comparing two LEDs, look at the spectrums of the two fixtures because this will affect plant performance.

Q: What PPFD levels do you recommend for the vegetative state of growth and then into flower?

A: We’re very strategic in our intensity and photoacclimation approach and we’re pushing more and more to get to that high intensity quicker. We’re developing SOPs to help train and guide cultivation staff on this. If we’re talking about veg, we’re going to typically start out at about 250 PPFD. And then we’re going to ramp up that intensity until the end of the veg cycle to the 550 to 600 micromole range as a max veg intensity. We’re recommending about 50 micromoles-a-day increases. We might start out flower at 650 to 750 PPFD.

Q: What factors influence canopy penetration?

A: The growth stage is one factor, and the number of leaves — density— also matters. Be sure you are targeting the correct DLI.